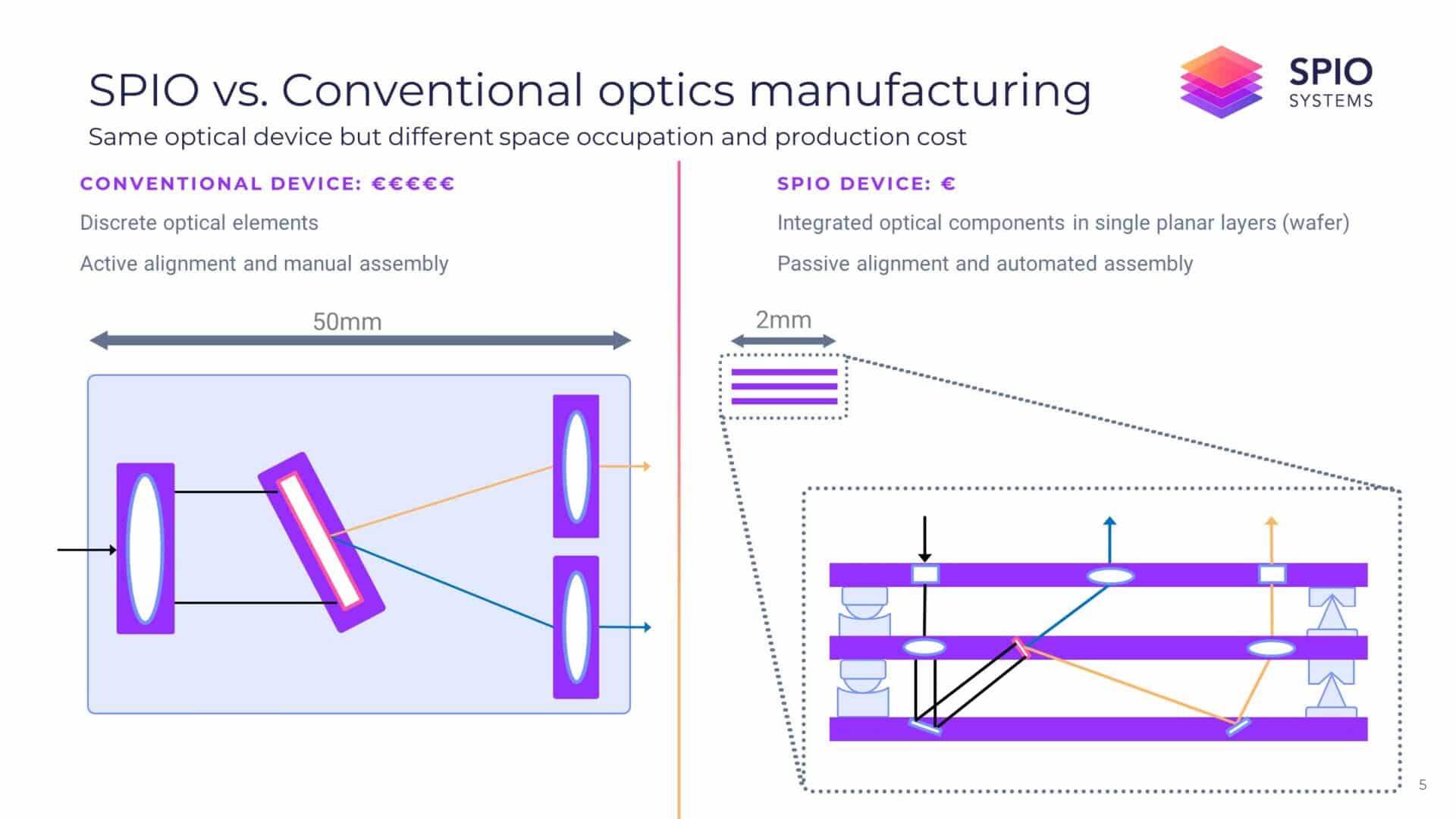

SPIO - Stacked Planar Integrated Optics - is a production technology that allows mass production of small-size optical devices with photonic component integration.

Get in touch- 1

We convert your free space optical setups into designs that can be realized as a SPIO module

The core functionality of your optics is in center, when we make the design. We use Zemax to simulate our designs and work in close collaboration with our customers, to ensure the performance of the optics.

- 2

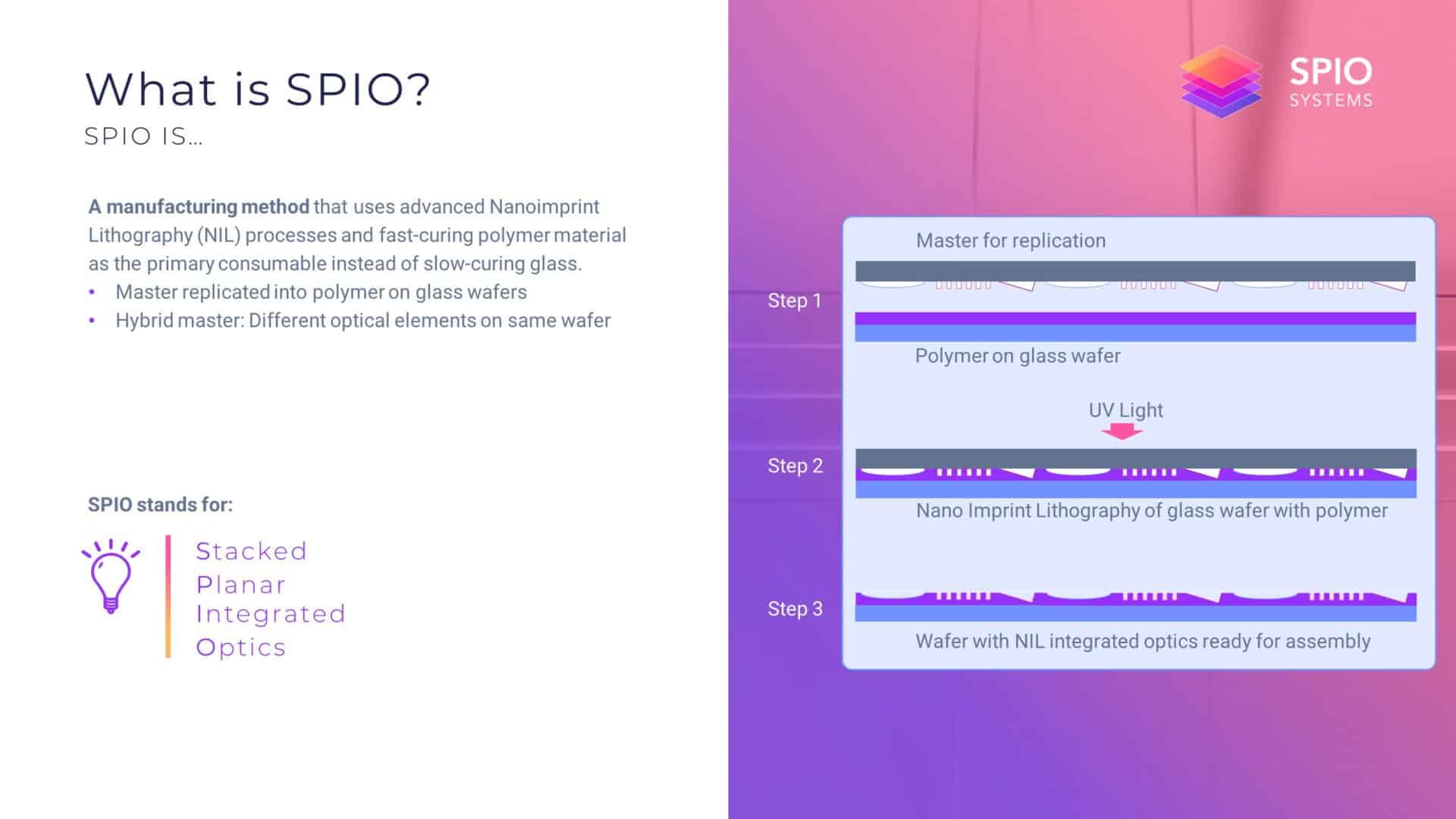

We print your optics in polymer on glass wafers.

The printing process is called Nanoimprint Lithography, utilizing a roll-to-plate approach. Hundreds of module parts can be printed on a single glass wafer.

The modules can consist of lenses, mirrors, gratings and optical coatings - and even freeform shapes! - 3

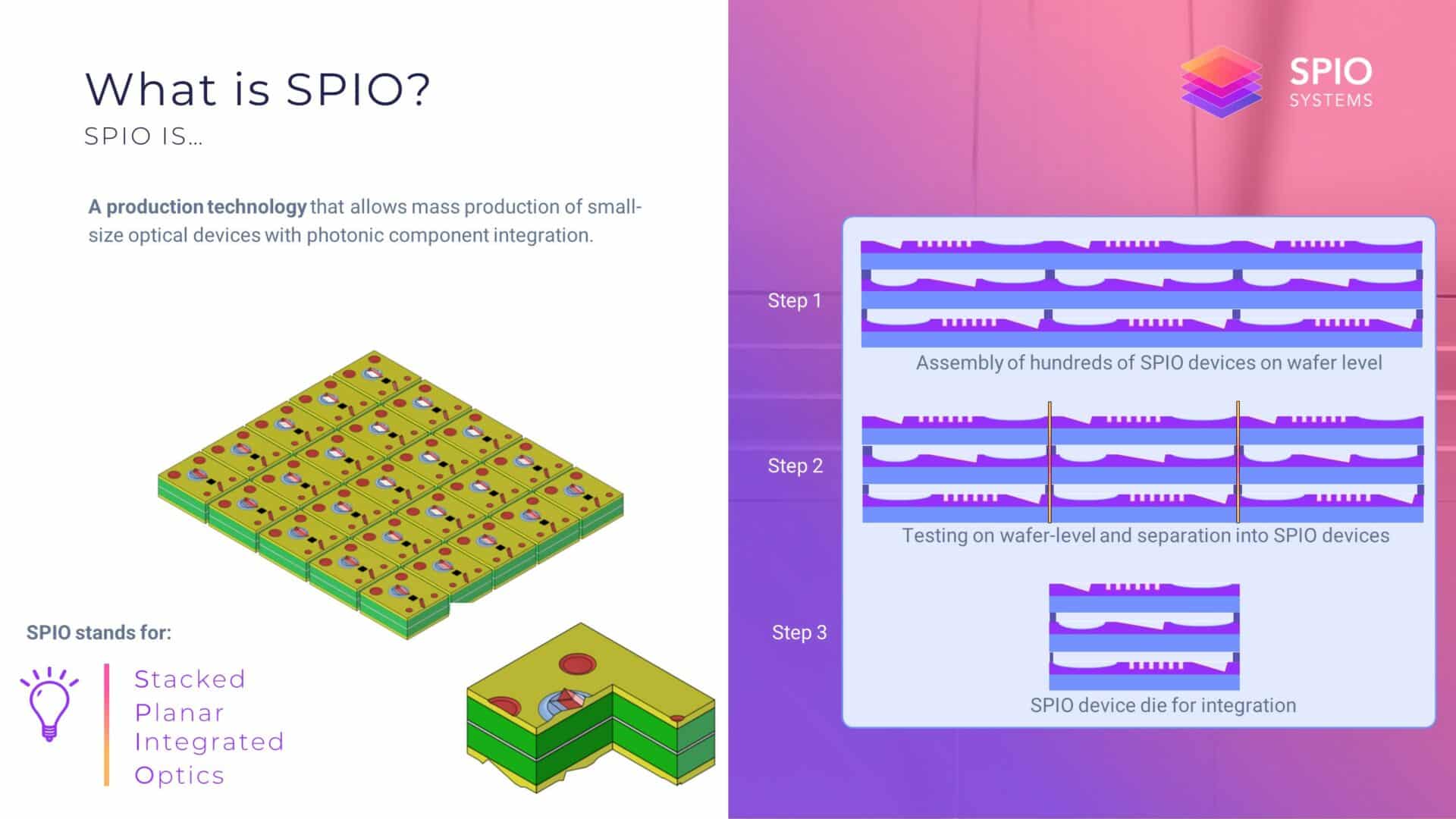

We align and stack the wafers to micrometer precision.

The imprinted wafers are bonded together with glue. The distance between the layers are ensured by various spacers, such as spheres.

- 4

The stacked wafers are singulated into seperate SPIO modules.

Your final SPIO module is a fully functional, passive optical component - only a few mm in size!